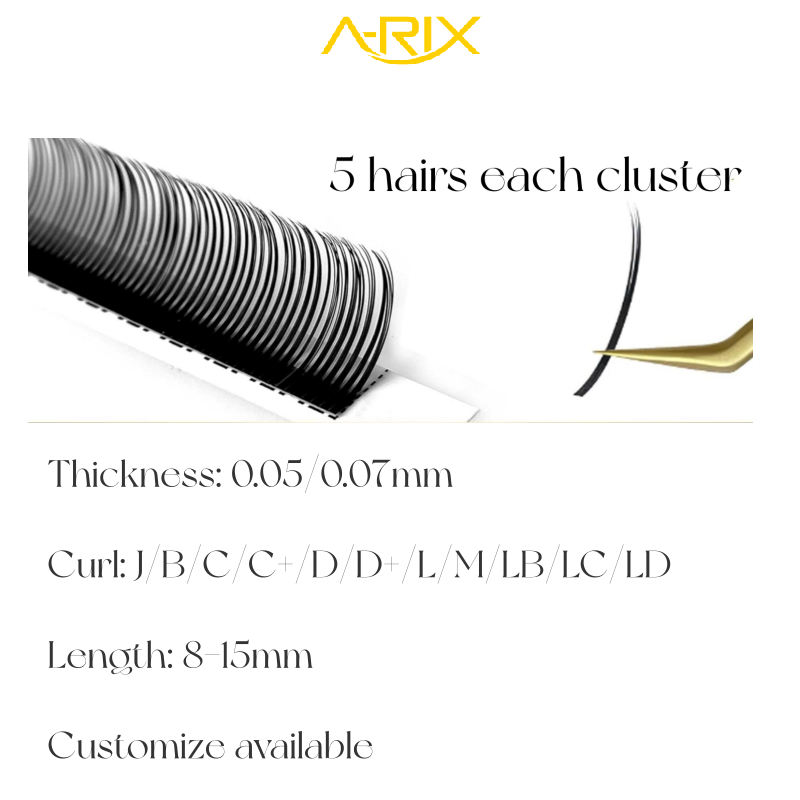

We can customize volume eyelash extensions according to different techniques for making lash fans and control the cost to give our customers the most cost-effective products simultaneously.

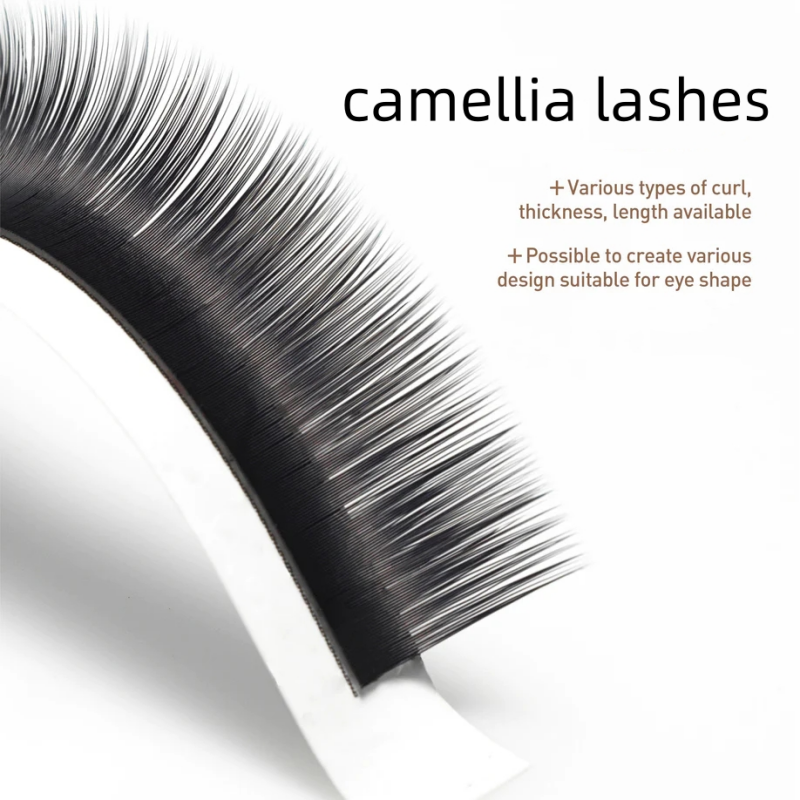

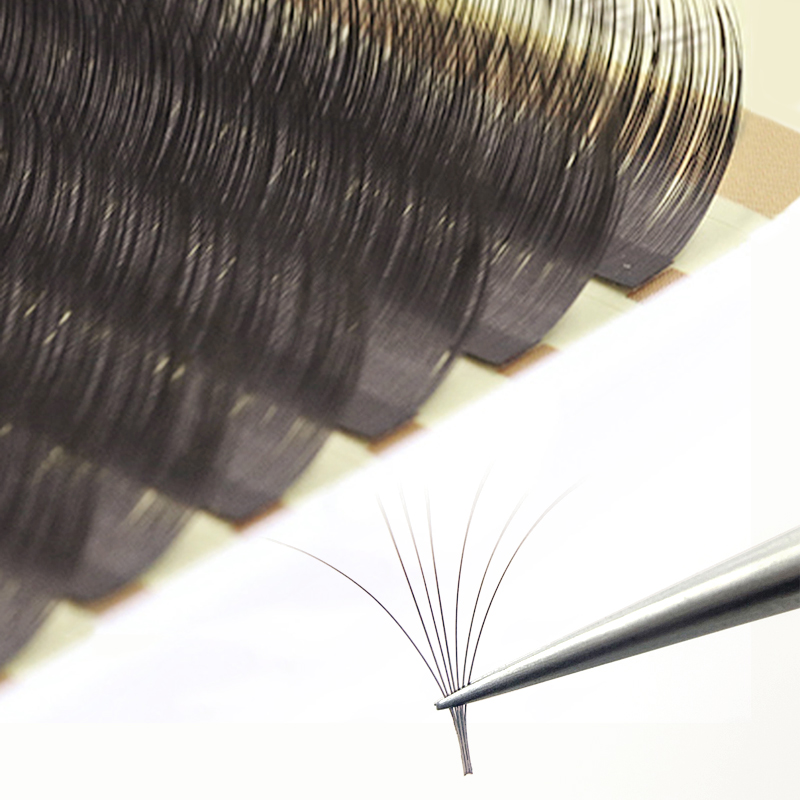

Our machine-pressed eyelashes and handmade eyelashes are suitable for different lash fanning techniques. Machine-pressed volume lash has a larger gap, which is better for the “shimmy” or “glide” lash method instead of the “sticky strip” method. While each hair of our hand-made volume lash extension is arranged with an acrylic mold. The little gap is perfect for any lash fan-making method.

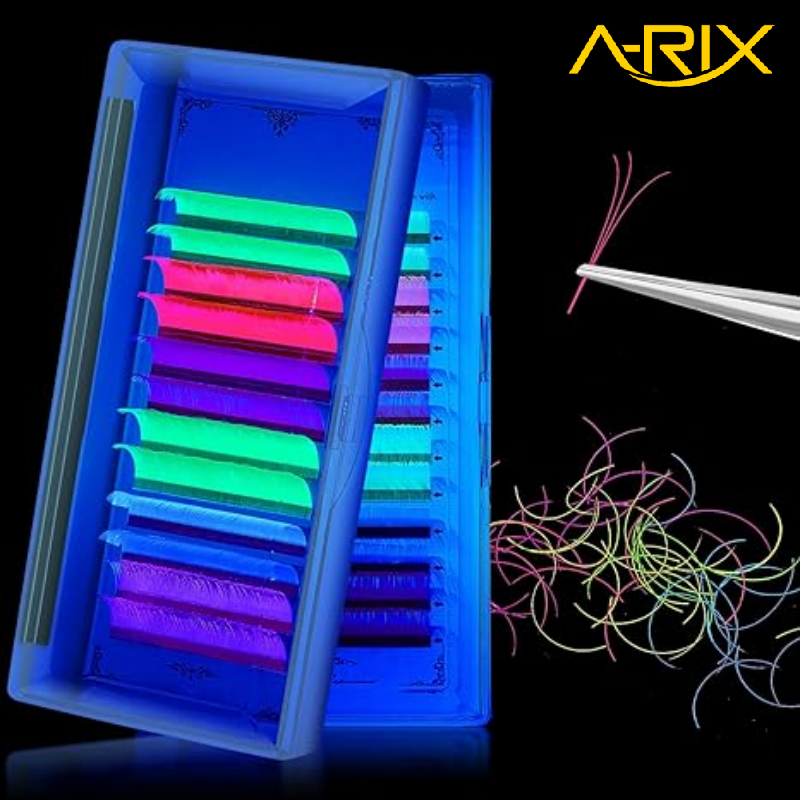

It is undeniable that there are too many customers who love thick and curled eyelash extensions. Volume eyelash extensions can make your job a lot easier. We are a professional eyelash extensions manufacturer and supplier in China, we can help you customize and wholesale volume eyelash extensions, expand your eyelash product line.

Why do lash fans fall apart easily?

In addition to the influence of the fanning techniques, the raw material also has an impact. It is possible that the easy-fall-apart lash fans are caused by using machine-pressed volume eyelash extensions or the uneven diameter of the lash raw materials.

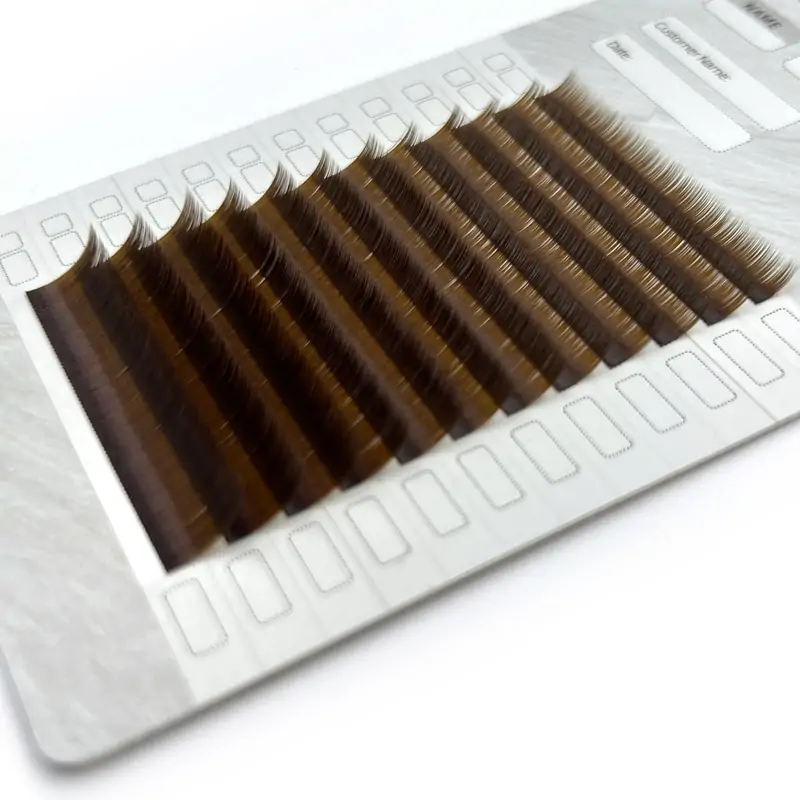

Why do I have glue residue on the base when I pick up the hair?

This is because the tape is overflowing with glue. There may be glue residue on the tape if the production temperature is too high or if substandard tape is used. The adhesive tape used for the eyelashes is a high-temperature pressure-sensitive tape of polyimide tape or masking tape. The distinct difference is that the color of the two tapes is different. Most of the dark brown tape is polyimide tape, and the red one is masking tape. What matters more is the colloid itself. The 3M or Dow Corning High-Temperature Adhesive tapes we use are a safer option.

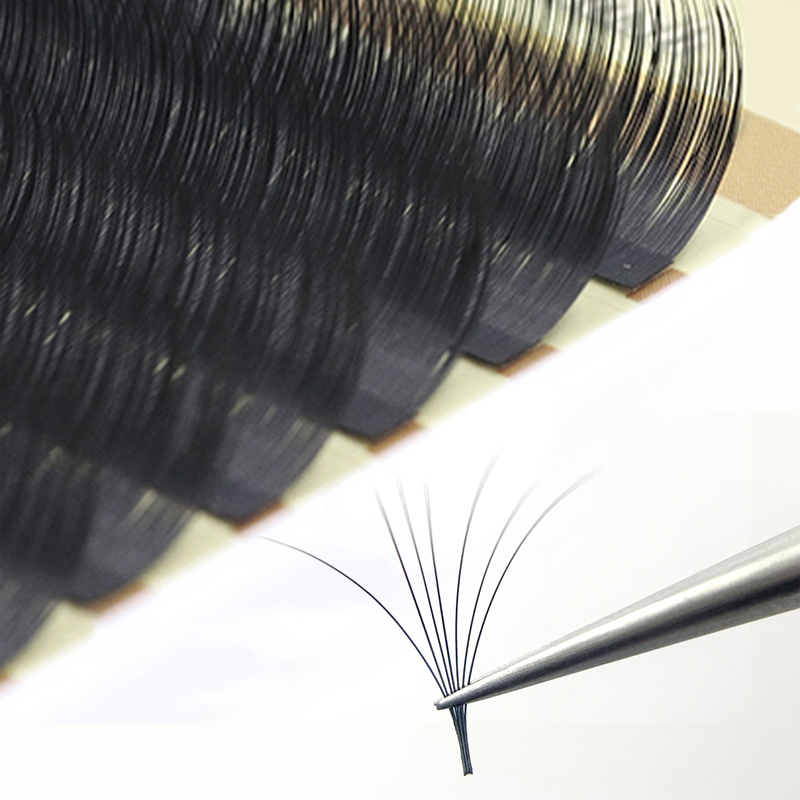

How do we help customers develop products?

Bella is the CEO of an American eyelash brand. During eyelash training courses, especially in volume lash technique courses, some beginners who are weak in learning or older often have shaky hands and the fans are easy to lose. It is difficult for beginners to learn volume techniques in a short time. And if they use easy fanning lashes for training, there will be another problem of shrinking and too much glue on the base. LISA, as the director of the A-RIX R&D department, recommended a product we developed for the fast lash application market in response to the problems they encountered. We created a unique production process to make a very thin glue at the base of the volume lash. The layer of that glue makes the fans not easy to lose. Furthermore, the thin glue won’t react with the adhesive to make the fan shrink easily. The volume eyelash fanning techniques become easier to learn for the students because of that. The new volume lash product improves the learning efficiency of the students and also helps Bella to improve their training efficiency simultaneously.